DOT tire regulations: Fleet safety best practices + checklist

Learn how regular tire inspections and DOT tire regulations keep your fleet safe and compliant.

Key Insights

- DOT tire regulations specify minimum tread depths (e.g., 4/32 inch for steer tires and 2/32 inch for drive tires) to ensure that commercial vehicles maintain safe traction and handling on the road.

- Routine tire inspections and tread depth measurements are essential for fleet safety. They help prevent tire failures and ensure compliance during DOT audits.

- Adhering to DOT tire regulations promotes road safety, reduces maintenance costs and improves overall operational efficiency.

Non-compliance with tire regulations can lead to costly fines, increased liability,, potential out-of-service orders and preventable accidents.In fact, tire-related accidents resulted in 562 fatalities in 2022, underscoring the critical importance of tire safety.

DOT tire inspections are mandatory assessments designed to verify that commercial vehicles meet DOT tire regulations set by the U.S. Department of Transportation (DOT) National Highway Traffic Safety Administration (NHTSA). These inspections evaluate various tire conditions to ensure vehicles operate safely while adhering to federal standards.

Regular checks and maintenance help prevent accidents and ensure that your fleet is prepared for a DOT audit, keeping compliance and safety at the forefront of your operations. Explore everything about DOT tire regulations and how to measure tire depth.

What is tire tread depth?

As the name suggests, tire tread depth is the tread thickness on tires. It plays a key role in fleet safety, ensuring commercial vehicles maintain grip, reduce stopping distances and channel water away on wet roads. Fleet vehicles face a higher risk of hydroplaning and reduced traction without adequate tread depth, especially in adverse conditions.

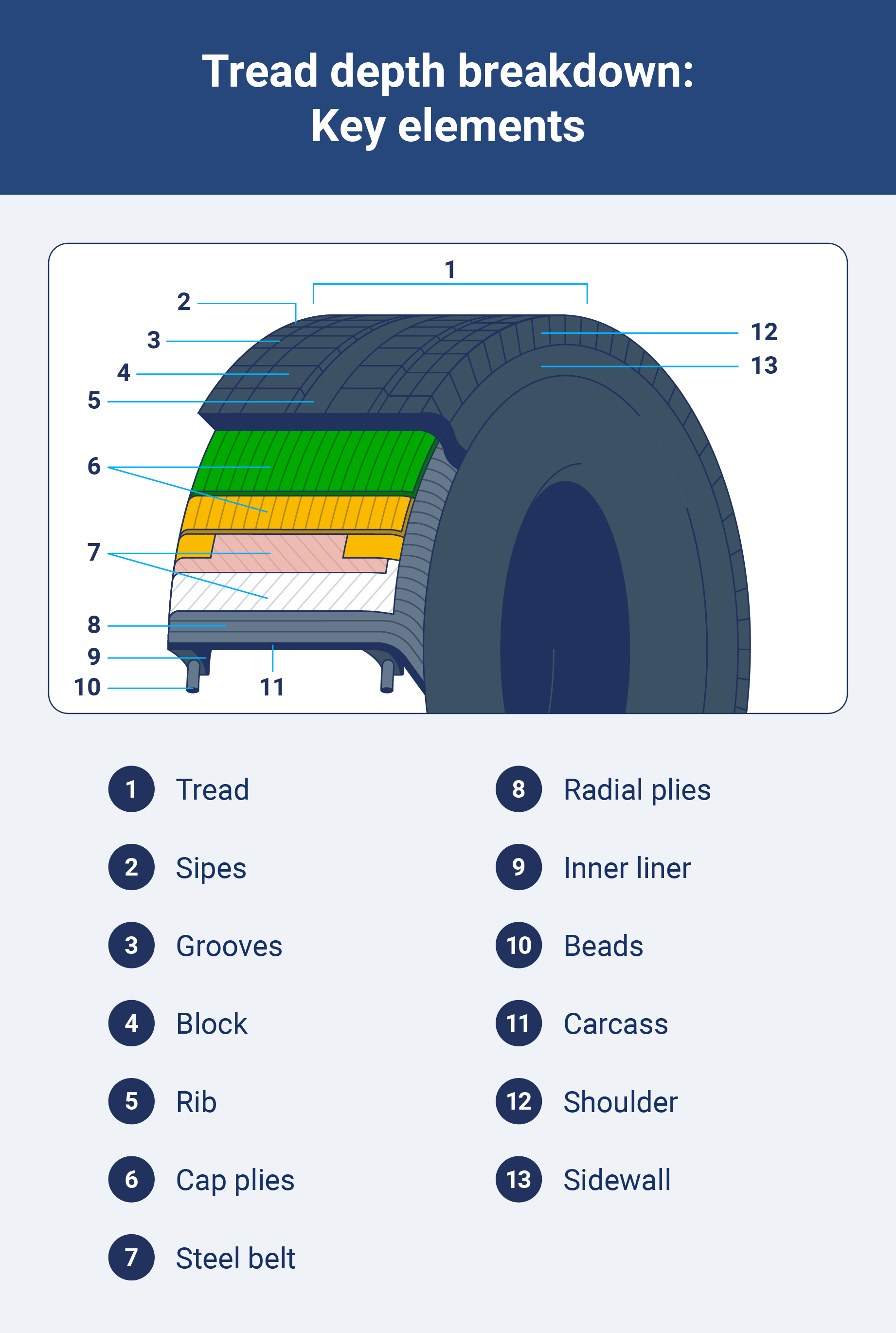

Key components of tire tread depth include:

- Ribs: Continuous raised sections of tread that run circumferentially around the tire, helping with stability and even wear

- Blocks/lugs: Individual segments of tread that provide traction and grip, especially on uneven surfaces

- Grooves: Deep channels that run between tread ribs or blocks, designed to disperse water and prevent hydroplaning

- Voids: Open spaces between tread blocks that enhance off-road grip and improve mud or snow traction

- Sipes: Thin slits in tread blocks that improve traction on wet or icy surfaces by creating additional biting edges

With 13 million large trucks on U.S. roads, accounting for 5% of all registered vehicles, ensuring these trucks adhere to tire safety standards is crucial for the safety of all road users. Proper tire maintenance and compliance with DOT regulations protect your drivers and enhance overall traffic safety.

The importance of checking DOT tire tread depth

Regular checks of DOT tire tread depth ensure fleet safety. Worn-out treads can lead to reduced traction, longer stopping distances and increased risks of hydroplaning, making it essential for a robust fleet driver safety program to include regular inspections and maintenance.

Maintaining proper tread depth protects drivers and cargo and ensures compliance with regulatory standards. Integrating routine tread assessments into your fleet driver safety program helps you minimize accidents, reduce liability risks and promote a proactive safety culture.

DOT tire regulations and requirements

DOT tire regulations are designed to ensure safety and compliance by setting clear standards such as the CSA score. Adhering to these guidelines is essential for maintaining a robust fleet driver safety program.

Tread depth

Maintaining sufficient tread depth in commercial truck tires is critical to ensuring traction, proper water dispersion, and overall road safety. DOT regulations generally set minimum tread depths that help reduce the risk of hydroplaning and ensure effective braking under adverse conditions.

Commercial truck tires are typically expected to meet or exceed minimum tread depth requirements. Here’s a simplified tire depth chart of common standards:

Category | Minimum acceptable tread depth |

|---|---|

| Minimum legal tire tread depth (passenger) | 2/32 inches |

| Minimum winter Tire tread depth | 4/32 inches |

| Required commercial tire tread depth | 4/32 inches (for steer tires) |

| Commercial vehicle tire tread depth | 2/32 inches (drive tires) and 4/32 inches (steer tires) |

| Dangerous tire tread depth | Below 2/32 inches |

| Recommended replacement depth | 4/32 inches |

Tire pressure

Maintaining proper tire pressure ensures safe operation and efficient fuel consumption. Under-inflated tires can overheat and wear unevenly, while over-inflated tires may reduce the contact patch, compromising traction and stability.

Regular pressure checks with an accurate gauge ensure that each tire meets the manufacturer’s recommended levels, contributing to a safer fleet overall. Accurate tire pressure also helps avoid premature tire wear and plays a significant role in the vehicle's braking performance and handling.

Steer tires

Steer tires are subject to stringent regulations, given their critical role in vehicle control, especially in semi-trucks and commercial trucks. Key points include:

- Minimum tread depth: Steer tires typically require a minimum tread depth of 4/32 inches to ensure optimal performance.

- Inspection frequency: Regular, often monthly, inspections are essential to detect early signs of wear or damage.

- Load ratings and balance: Ensuring that steer tires are correctly balanced and not overloaded is vital for maintaining handling and safety.

The emphasis on semi-truck steer tire tread depth is higher for semi-trucks and commercial trucks due to their unique operational demands and the potential impact on overall vehicle stability.

Age laws

Tire age is as important as tread depth in terms of fleet safety. Even if a tire appears to have sufficient tread, aging rubber can lead to reduced performance and an increased risk of failure. Typically, tires should be evaluated for replacement after 6-10 years, depending on usage, storage conditions and manufacturer recommendations.

Regular assessment of tire age ensures that fleet vehicles do not run on tires that have degraded over time, thereby reducing the risk of unexpected tire failures and enhancing overall road safety.

Inspections

Regular tire inspections are a cornerstone of fleet maintenance and safety programs. Systematic evaluations help identify issues such as uneven wear, punctures or other damage early on, preventing potentially hazardous situations.

Proper repair procedures should be followed promptly to ensure any identified issues are resolved in compliance with DOT regulations. This proactive approach not only improves tire longevity but also minimizes downtime and reduces liability risks for fleet operators.

How to measure tire tread depth

Measuring tire tread depth is an essential maintenance step that directly impacts fleet safety and helps manage fleet costs. Maintaining the minimum tread depth for drive tires keeps vehicles compliant and prevents unexpected expenses from premature tire wear or failure.

1. Choose a tire tread depth tool

Select a reliable tire tread depth gauge or even a coin as an alternative tool. This instrument is essential for quickly determining if your drive tires meet the minimum tread depth for drive tires, ensuring both safety and cost efficiency within your fleet.

2. Find the lowest spot on the tire

Inspect the tire to locate the area with the least tread depth — typically found in the center of the groove. This lowest point is the most accurate indicator of overall tire wear and is critical for deciding when a tire needs replacing to prevent increased fleet costs.

3. Push the tool into the tread

Firmly press the tire tread depth tool into the groove at the identified lowest point. Ensure the tool is perpendicular to the tire surface to guarantee an accurate reading, which is vital for making proper maintenance decisions.

4. Read the measurement

Carefully note the measurement on the gauge and compare it to the recommended minimum tread depth for drive tires. If the tread depth falls below the threshold, it’s time to schedule a tire replacement to maintain fleet safety and manage long-term fleet costs.

Fleet tire safety tips and best practices

The easiest way to keep your fleet safe is to adhere to federal DOT tire regulations while using predictive maintenance strategies. Regular maintenance prevents accidents and helps catch issues early. Here are some tips to further enhance your fleet tire safety:

- Regularly check tire depth: Incorporate tire tread depth inspections into your daily pre-trip inspection checklist. Regular checks help identify wear patterns early and ensure that tires meet the minimum safety requirements before every journey.

- Rotate tires every 3 months (or 3,000 miles): Rotating tires evenly distributes wear and extends tire life, reducing replacement costs. This practice also helps maintain balanced performance across all tires in the fleet.

- Don't exceed your tires' speed rating: Following the tire speed rating prevents overheating and premature wear, ensuring that tires perform as expected under varying driving conditions. Adhering to these ratings supports overall vehicle safety and performance.

- Check your valve stems and caps: Regular inspections of valve stems and caps are essential to prevent air leaks. Maintaining proper inflation enhances tire performance, contributes to fuel efficiency and prolongs tire life.

- Inspect your spare tire: Don't overlook your spare tire — ensure it’s properly inflated and free from damage. This is especially important considering the tire age limit law, which emphasizes replacing tires before they become a safety risk due to age.

- Use weather-specific tires when necessary: Switch to tires designed for specific weather conditions to maximize grip and safety. Whether it’s winter or summer tires, adapting to the weather improves traction and overall fleet safety.

- Keep tires properly inflated: Maintaining the correct tire pressure is crucial for even wear and optimal performance. Regular checks can help reduce fuel consumption while minimizing the risk of tire blowouts.

Optimize fleet tire maintenance with Geotab

Keeping up with all the DOT tire regulations while fleet maintenance can be challenging, but you can simplify the process by integrating Geotab’s innovative fleet management solutions.

With your fleet's safety as our top priority, we help you streamline maintenance, ensure compliance with DOT tire regulations, and reduce unexpected fleet costs. Explore our advanced fleet optimization software and how you can use it to monitor tire health and optimize your fleet maintenance!

Subscribe to get industry tips and insights

Frequently Asked Questions

The DOT tire rule sets federal safety standards for tires, including tread depth, construction and performance requirements to ensure that tires used on commercial vehicles meet minimum safety criteria.

A tire becomes DOT-approved by meeting strict federal safety standards, which include proper labeling, construction and performance metrics. It will feature a DOT code on its sidewall, indicating compliance.

You must maintain a minimum of 4/32 inch steer tire tread depth to ensure safe handling and optimal performance, particularly for commercial trucks.

For front tires, the minimum tread depth is generally 2/32 inches for passenger vehicles, but for commercial trucks, front steer tires are expected to maintain at least 4/32 inches.

Driving on a tire with a 2/32-inch tread is unsafe, as it is below recommended levels for most vehicles, increasing the risk of hydroplaning and tire failure.

The Geotab Team write about company news.

Table of Contents

Subscribe to get industry tips and insights

Related posts

Unlocking Safer Roads: How Behavioral Science and Technology Are Improving Driver Safety

April 14, 2025

2 minute read

How a well-built fleet safety culture prevents legal trouble

March 28, 2025

5 minute read

Driver behavior monitoring systems: Fleet managers’ guide for top tools + implementation tips

March 27, 2025

7 minute read

How AI-based in-cab video can lower fleet insurance costs and improve safety

March 24, 2025

3 minute read

Why driver incentive programs fail and what fleets can do about it

February 27, 2025

5 minute read

Driver incentive programs to improve safety, retention and fleet efficiency

February 7, 2025

4 minute read