Extend vehicle lifecycle with maintenance reminders and reporting

Maintenance management and engine diagnostic reports are essential to the longevity of fleet vehicles.

When vehicle deliveries are delayed, preventative maintenance is critical to extending the health and life cycle of existing fleet vehicles. With current vehicles being kept in service for longer periods, or kept in prime condition to be repurposed for other business opportunities, increasing communication around maintenance should remain a top priority.

Though scaling back your preventative maintenance efforts may seem like a good idea to temporarily cut costs, it could also have costly consequences. Skipping vehicle checks could lead to smaller problems growing into bigger ones.

For example, extending oil changes beyond their scheduled date means fewer courtesy checks, which can result in a higher risk of undetected brake wear and tear, low fuel levels for oil, transmission and brakes, incorrect tire pressure or lack of tire rotations. Short term cuts can cost your business more later on, so following manufacturer (OEM) or fleet management-recommended preventative maintenance schedules is more essential than ever.

See also:

Measuring fleet productivity and managing downtime

How to maximize fleet asset utilization

Why use telematics in an economic downturn?

Why maintenance management matters

When it comes to fleet maintenance, when you do it can affect how much it will cost. For example, an oil change for a medium-duty diesel engine costs roughly $120. However, by neglecting regular oil change reminders, the lack of maintenance can lead to irreparable engine failure, possibly costing upwards of $5,000 for a full engine replacement or more if replacing the vehicle entirely.

Similarly, spending $50 to $75 for regular tire rotations far outweighs the $800 or more cost of replacing the tires or risking blowouts while on the road. If neglecting regular preventative maintenance, the replacement costs can add up to more than the regularly recurring costs.

Understanding the reminder rule in MyGeotab

For fleets that are not part of a fleet management service company, the reminder rule is a great way to help you stay on top of maintenance. This highly customizable free rule can be built off of any combination of time, engine hours or mileage, any of which can trigger an alert. Once a notification is triggered and new maintenance is entered, all three counters reset.

Setting up reminders

To begin, you only need to gather and input the vehicle’s most recently completed maintenance items. A full vehicle life history is not required. Resellers or Customer Service Specialists can assist with set-up or you can follow the steps outlined in our How to Schedule Maintenance Reminders video.

Other uses of this rule can include license plate renewals, safety checks, emission checks and annual driver physicals. Additionally, downloading the free Dynamic Vehicle Maintenance Reminder Report will also make notifications more efficient.

.png)

Save money with engine diagnostics

Cost containment is critical in uncertain times. Having a system in place to warn fleet managers about potential issues allows fleet managers to take proactive steps towards resolution.

In addition to the built-in rules, here are two other helpful rules.

Go-to rules in MyGeotab for maintenance:

- Engine Light On — This rule identifies vehicles driving with the “Check Engine” light on and can be used to schedule maintenance or prevent serious issues. The average time to clear a check engine light is 90 days. That means 90 days of performance that could have been optimized.

- Battery Drain — Detects vehicles that have a battery voltage below 9 volts. Alerts from this rule can help identify general battery problems, or remind drivers to turn off their vehicle lights. Helping drivers avoid a dead battery also helps prevent missed service calls, loss of work time and tow truck bills.

Key diagnostic reports

Reporting on fault codes is useful for troubleshooting and understanding the severity of vehicle issues. These reports are dashboard-ready and can be emailed daily or weekly:

1. Engine fault report

This report identifies vehicle-based faults from the Engine Control Module (ECM) and provides the controller and diagnostic code. For more information on setting up this report, you can check out our video here: How to View Engine Faults in MyGeotab. Consider also setting up notifications for the fleet mechanic, fleet management company or other stakeholders, who can act on this information.

2. Telematics fault detection report

This report delivers a breakdown of which devices are experiencing faults, the type of faults, and how they can be resolved. This report is valuable for detecting issues such as: Low Battery Voltage, General Vehicle Warning Light, and Low Priority Warning Light On.

Check out our Cost Control Strategies webinar to review this information on maintenance reminders and engine diagnostic reporting. Find even more ideas for fleet maintenance management on the Marketplace.

Subscribe to get industry tips and insights

The Geotab Team write about company news.

Table of Contents

Subscribe to get industry tips and insights

Related posts

How to avoid high downtime costs for construction fleets

March 10, 2025

2 minute read

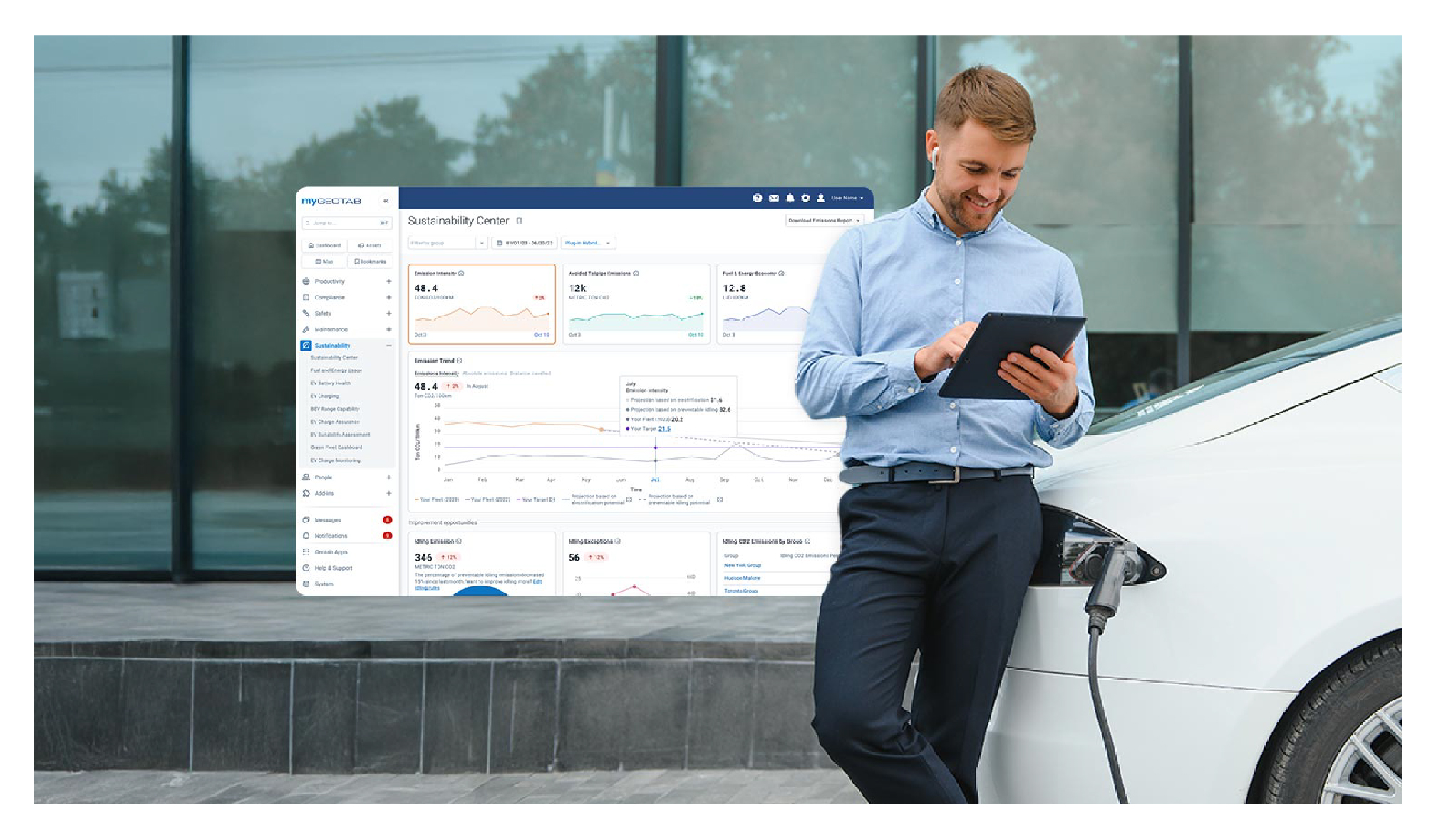

Geotab’s new fleet Sustainability Center simplifies fuel and emissions reduction

March 3, 2025

3 minute read

Empowering Choice: The Power of Collaboration in Our Marketplace

January 15, 2025

1 minute read

Top 7 Transportation Management Systems (TMS) Software

December 5, 2024

7 minute read