Southern Wine and Spirits of America: Managing drivers

Table of Contents

The Challenge: Safely and productively managing drivers

With operations spread across 35 states, Southern Wine & Spirits of America, Inc. (Southern) faces the challenge of safely and productively managing its drivers and fleet vehicles across 6,000 miles and 187,000 customers.

Due to variations in state liquor laws — some that date back to the end of Prohibition — standard operations with specialized attention to the local regulations and business practices are key to meeting a high level of customer service. This is done while simultaneously ensuring all applicable state laws governing the distribution of wine and spirits are followed. Needless to say, it’s a challenge.

Southern’s customer delivery strategy leverages the main fleet vehicle — a 33,000-lb. GVWR straight truck. Using a short box CDL straight truck allows the company the flexibility it needs to travel in tightly congested urban areas, particularly when delivering to a variety of large and small customers. Southern’s typical distribution center stocks about 13,000 different items which a restaurant, convenience store, grocery store, mass merchandiser, or any other customer may need. Order sizes range from a few bottles or cases of wine and spirits, to large bulk orders delivered on pallets.

“It’s a very dynamic situation from a delivery and customer service perspective,” says Larry Sullivan, Southern Wine’s Vice President of Fleet, Safety and Compliance. “Our employees are highly trained and Southern’s facilities are highly automated to allow our customers to place their orders by 5 p.m. and have it delivered to your door when you need it.” Sales reps input orders throughout the day and at 5 p.m. the distribution centers stage and pick product for delivery to Southern customers as scheduled.

The solution

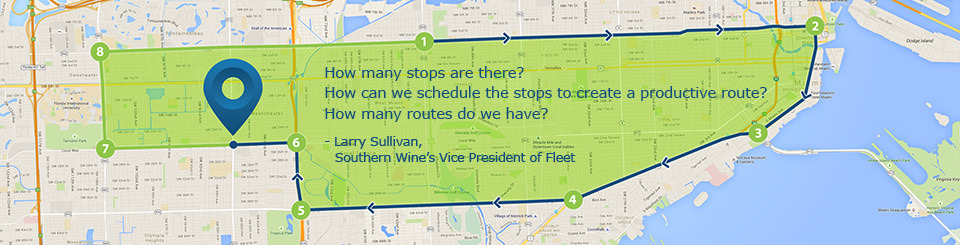

Different customer orders vary, which means new routes and schedules every day. “That’s where things can really start to get interesting,” Sullivan says, listing several questions that Southern’s logistics team must sort through: “Where did the orders come from? How many stops are there? How can we schedule the stops to create a productive route? How many routes do we have? How many trucks do we have available to load? and so on,” he adds.

The need for flexibility and a productive delivery operation has driven the company to leverage vehicle telematics to streamline operations from warehouse to customer and back. “Our routing and telematics systems have to be flexible, easy to use and scalable,” Sullivan says.

Southern’s telematics provider of choice for the last four years has been Geotab.

The results

The numbers continue

Using Geotab telematics, Southern can plan out each route based on how the orders will be delivered. Using information from a Geotab software partner that is tightly integrated with the Geotab system, the time spent for each order and drive time between each delivery is tracked - giving the company insight into each delivery and stop time. This type of best practice software integration is why the company chose Geotab as their telematics provider.

“The telematics value-add is the software and features that provide value to your company’s specific operations strategy,” Sullivan says. Every minute has to be accounted for as one delivery should take 20 minutes while another might take 45 minutes. If one goes over, it creates a trickle effect for the deliveries the rest of the day. “One reason we chose Geotab is because their hardware allowed us easily to integrate with our routing software — enabling us to optimize our routing based on feedback from the location information provided by the telematics,” he adds.

The tracking information also allows Southern’s dispatch to update customers on their deliveries, including any delays or early deliveries.

Getting sophisticated

As transparency in route timing has increased, Southern is able to make adjustments on routes so that delivery times can be more accurate in the routing system.

“We surmised, if we can save one minute on 20 stops every day, we might be able to add another stop,” Sullivan comments. “And if we can add another stop to 100 trucks, we can use fewer trucks that day — and that adds up to significant efficiencies that we can pass on to our customers. Transparency in route timing was the first feature that got us interested in Geotab because no one else was working with our routing system to bring us to this level of integration.”

Beyond improved routing, Southern focuses on several other features to increase their benefit from telematics. Starting with idling, Sullivan says even without the improved routing, savings in idling alone justifies the ROI on telematics hardware.

“When we started to take a hard look at the idling our trucks were doing each day, our team quickly saw an excellent opportunity for additional productivity and expense savings.”

Enhanced visibility to speeding and re-creating occurrences of driver speeding are also an important benefit of telematics and helps to enhance the safety of Southern’s drivers and others on the road. The company posts a 1-800 phone number on their trucks for other drivers to compliment or comment on their drivers. Having the telematics system and being able to substantiate or discredit a claim of speeding has been helpful, and provides objective information that can be used to coach Southern drivers to continue operating safely.

Southern also uses seatbelt sensors tied to the telematics solution to promote and monitor seatbelt use, while fuel consumption and increasing the overall fleet MPG is another vital focus for the Southern fleet. Southern is in the early stages of using the telematics solution to understand their use and consumption of fuel. At this point, Southern stands behind the tool as a way to highlight problem areas and point out areas for improvement and fuel reduction.

Southern also uses data from the telematics to examine hard stops and fast starts. “Carrying bottles, minimizing breakage and delivering undamaged product to our customers is vital in our business,” Sullivan says. The company is currently working on how to correlate these types of stops and starts with the amount of bottle damage in the trucks. The Southern team follows up with drivers to understand why hard stops might be happening, and then uses the feedback to schedule and train drivers to improve upon their driving skills and how to maintain the proper distance between vehicles.

Southern has gone beyond the basic use of telematics data to create its own processes and analytics to maximize ROI. The company is constantly reviewing and refining ideas to extend the use of data compiled by the Geotab devices. “The basic information we get from Geotab, we utilize intensively and feel the data is valuable in driving a positive ROI,” Sullivan says.

From The Fleet Manager

“From a CSA-compliance standpoint, one of the highest point violation citations our drivers receive is a seatbelt violation. It is important to us that we have this tool to remind drivers that our No. 1 priority is getting that driver safely through their route and home to their family every night."

— Larry Sullivan, Southern Wine’s Vice President of Fleet, Safety and Compliance.

Post Tags

Client profile

Client name:

Southern Wine & Spirits of America, Inc.

Industry:

Wine, spirits and beer wholesaler

Types of vehicles:

Straight trucks, tractors/trailers, vans

Fleet size:

2200

Fleet focus:

Safety, Fleet Optimization, Productivity

Other stories

PepsiCo TR instills fleet safety at the heart of its operations with Geotab

June 11, 2024

Grupo Crío: Ensuring driver safety

May 8, 2017

Second Harvest: Benefiting from telematics

May 19, 2015