What are maintenance service intervals?

April 9, 2025

•5 minute read

Key Insights

- Maintenance intervals are scheduled service milestones when vehicles should undergo inspections, fluid changes, component replacements, and other servicing to maintain optimal performance.

What are maintenance intervals?

Maintenance intervals are scheduled service milestones when vehicles should undergo inspections, fluid changes, component replacements, and other servicing to maintain optimal performance. They are usually based on odometer readings, operated engine hours, or number of days since last service, and show fleet managers which services are recommended at what time. In this glossary blog post, we will review why maintenance intervals are important, how maintenance intervals vary for different vehicle types, key areas to focus on in vehicle maintenance and other best practices for fleet managers.

Why are maintenance intervals important?

General importance

The better an operator maintains a vehicle, the more effectively that vehicle will function over the long term. Regular maintenance helps prevent unexpected breakdowns, improves vehicle longevity and promotes compliance with manufacturer warranties. In short, following maintenance intervals is key to optimizing a vehicle’s performance.

Importance for fleets

Adhering to maintenance intervals allows fleet managers to maximize the lifetime of each vehicle by minimizing downtime and cutting operational costs. Conversely, neglecting service schedules can lead to more costly repairs, regulatory violations and decreased fuel efficiency. Following maintenance intervals also improves safety by making vehicles more reliable and less prone to breakdowns. Effective fleet management requires a proactive approach to vehicle maintenance that considers vehicle type, usage patterns and environmental conditions.

Maintenance intervals for different types of vehicles

Maintenance intervals often follow the 30-60-90 rule as a common guideline, which means fleet managers or operators should perform specific maintenance tasks when a vehicle reaches 30,000, 60,000 and 90,000 miles. However, different fleet vehicles have distinct service interval needs based on their function and workload. It is usually best to refer to each manufacturer’s recommendations for vehicle maintenance, but here are high-level maintenance guidelines for different vehicle types:

- Light-duty vehicles (sedans, SUVs and pickup trucks): These vehicles typically require oil changes every 5,000–7,500 miles and tire rotations every 6,000–8000 miles.

- Medium-duty trucks: These larger trucks should receive service and inspections every 10,000–25,000 miles, including oil changes, filter replacements and visual inspections. More in-depth maintenance like transmission fluid changes and brake inspections may be needed every 25,000 to 50,000 miles.

- Heavy-duty trucks: 18-wheelers and other large trucks require basic service every 10,000–20,000 miles, including oil and filter changes, and more comprehensive services like air and fuel filter replacement every 30,000 miles. These intervals can vary based on load and driving conditions.

- Off-road and construction vehicles: Because these vehicles often perform heavy work without driving long distances, their maintenance intervals are best scheduled using operated engine hours rather than mileage. They require maintenance checks after every 250–500 engine hours.

Key maintenance areas

Engine oil and fluid checks

A vehicle’s engine, transmission, brakes and other key components all rely on oil and various fluids to work properly. For example, engine oil is vital to lubricate an engine’s moving parts to help prevent wear and tear from friction. But over time, engine oil picks up contaminants like dirt that can clog engine passages and damage components. Regular oil filter changes are essential to removing these contaminants and extending the life of a vehicle’s engine—and with it, the vehicle itself.

Monitoring and regularly changing fluids for a vehicle’s brakes and transmission is also a key part of maintenance. Proper brake fluid levels are essential for hydraulic braking systems to function, so failing to maintain these can lead to worse handling and longer stopping distances. Dirty or low transmission fluid levels can make it more difficult for a vehicle to shift gears, leading to slipping gears or even transmission failure. Maintaining radiator fluid helps prevent a vehicle’s engine from overheating, which can cause significant damage. To know the right maintenance interval for your vehicles, consult their manuals.

Seasonal adjustments for optimal performance

Extremely cold or warm environments have different maintenance requirements to keep optimal vehicle performance, making it vital for your fleet to make seasonal adjustments in your maintenance schedules. For example, cold weather can diminish the lifespan of a vehicle’s battery, so it’s important to inspect batteries more often in the winter months. Freezing temperatures can also affect the water inside an engine’s cooling system, making it essential to maintain proper antifreeze fluid levels. Hotter seasons will demand more from a vehicle’s air conditioning and cooling systems, so it’s important to monitor these systems closely during summer. Extreme hot and cold weather also can take a toll on a vehicle’s tires, so pay close attention to tire pressure and condition as well.

Impact of driving condition on maintenance interval

Your fleet vehicles operate in all kinds of driving conditions, and this has a significant impact on how often vehicles need maintenance. Vehicles used primarily on highways may experience less wear and tear on their components compared to those that frequently brake and shift gears in stop-and-go urban traffic. Fleets operating in severe conditions like extreme temperatures, heavy loads, or off-road environments will require more frequent and specific servicing. For example, a dump truck that regularly hauls heavy materials across unpaved construction sites will need regular servicing of its hydraulic lifting systems and heavy-duty tires than a dump truck that typically carries planting soil and drives on suburban streets to parks and gardens.

Routine maintenance tasks

There are many routine maintenance tasks that are essential for keeping your fleet in top condition and limiting costly repairs, including:

- Oil and filter changes – Regular oil service helps keep engine components lubricated and free from debris, helping to prevent overheating and wear.

- Brake fluid exchanges – Brake fluid absorbs moisture over time, which can diminish brake performance and even lead to system failure. Regular flushing and replacement of brake fluid can help maintain braking performance and improve safety.

- Tire inspections and rotations – Checking proper tire pressure and monitoring tread wear extends tire life and improves fuel efficiency. By rotating tires at scheduled intervals, you can help prevent uneven wear patterns that shorten tire life.

- Battery and electrical system checks – Healthy batteries are essential for reliable vehicle performance, especially in extreme weather conditions. Regularly testing batteries and cleaning their terminals help prevent unexpected failures.

- Transmission and drivetrain inspections – Proper transmission function is important for vehicle performance. Be sure to regularly check fluid levels and health so you know when to flush and replace these fluids.

Preventive measures for longevity and reliability

Preventive maintenance is the key to extending the life of your fleet vehicles. This begins by establishing a comprehensive maintenance plan that includes scheduled servicing, pre-trip inspections and training for drivers to recognize and report issues. In addition, fleet managers should adopt telematics solutions to monitor vehicle health in real time, enabling predictive maintenance rather than reactive repairs. Using proactive strategies allows fleets to reduce downtime, lower repair costs and improve overall reliability for every vehicle.

Benefits of adhering to maintenance schedules

There are many benefits to following recommended maintenance intervals for your fleet. Here are the main reasons fleet managers should adopt a structured maintenance schedule:

- Cost savings – Preventive maintenance stops minor vehicle issues from causing expensive repairs or even total breakdowns, optimizing your repair budget and ROI on every vehicle.

- Increased safety – Regular servicing helps critical safety components like brakes and steering systems function properly to keep your drivers, vehicles and cargo safe.

- Regulatory compliance – Many industries require strict adherence to maintenance schedules to comply with safety and emissions regulations. By maintaining vehicles regularly, fleets can keep high Compliance, Safety, and Accountability (CSA) scores and help prevent fines.

- Improved fuel efficiency – Well-maintained vehicles operate more efficiently, reducing fuel consumption to help optimize your operational costs.

- Reduced downtime – Keeping vehicles in peak condition reduces the likelihood of lengthy repairs and unexpected breakdowns that could keep your vehicles off the road and disrupt fleet operations.

Frequently Asked Questions

A service interval is the manufacturer-recommended mileage, time frame or operating engine hour count for when you should perform routine vehicle maintenance.

A typical schedule includes oil changes every 5,000–7,500 miles, tire rotations every 6,000–8000 miles, brake inspections every 15,000 miles and transmission fluid changes around 30,000–60,000 miles.

- Preventive maintenance: Implementing routine servicing schedules of services like oil changes, tire rotations and fluid top-up to help prevent significant vehicle issues or failures.

- Predictive maintenance: Using real-time vehicle data from telematics solutions to forecast and address issues before they lead to extensive repairs.

- Corrective maintenance: Fixing noticeable issues like flat tires or worn-out brake pads before they cause vehicle breakdowns.

- Emergency maintenance: Also known as reactive maintenance, this is addressing unexpected failures that require immediate repairs before the vehicle is operational again.

Table of Contents

- What are maintenance intervals?

- Why are maintenance intervals important?

- Maintenance intervals for different types of vehicles

- Key maintenance areas

- Impact of driving condition on maintenance interval

- Routine maintenance tasks

- Preventive measures for longevity and reliability

- Benefits of adhering to maintenance schedules

Other Stories

What are the Federal Motor Vehicle Safety Standards (FMVSS)?

January 3, 2025

4 minute read

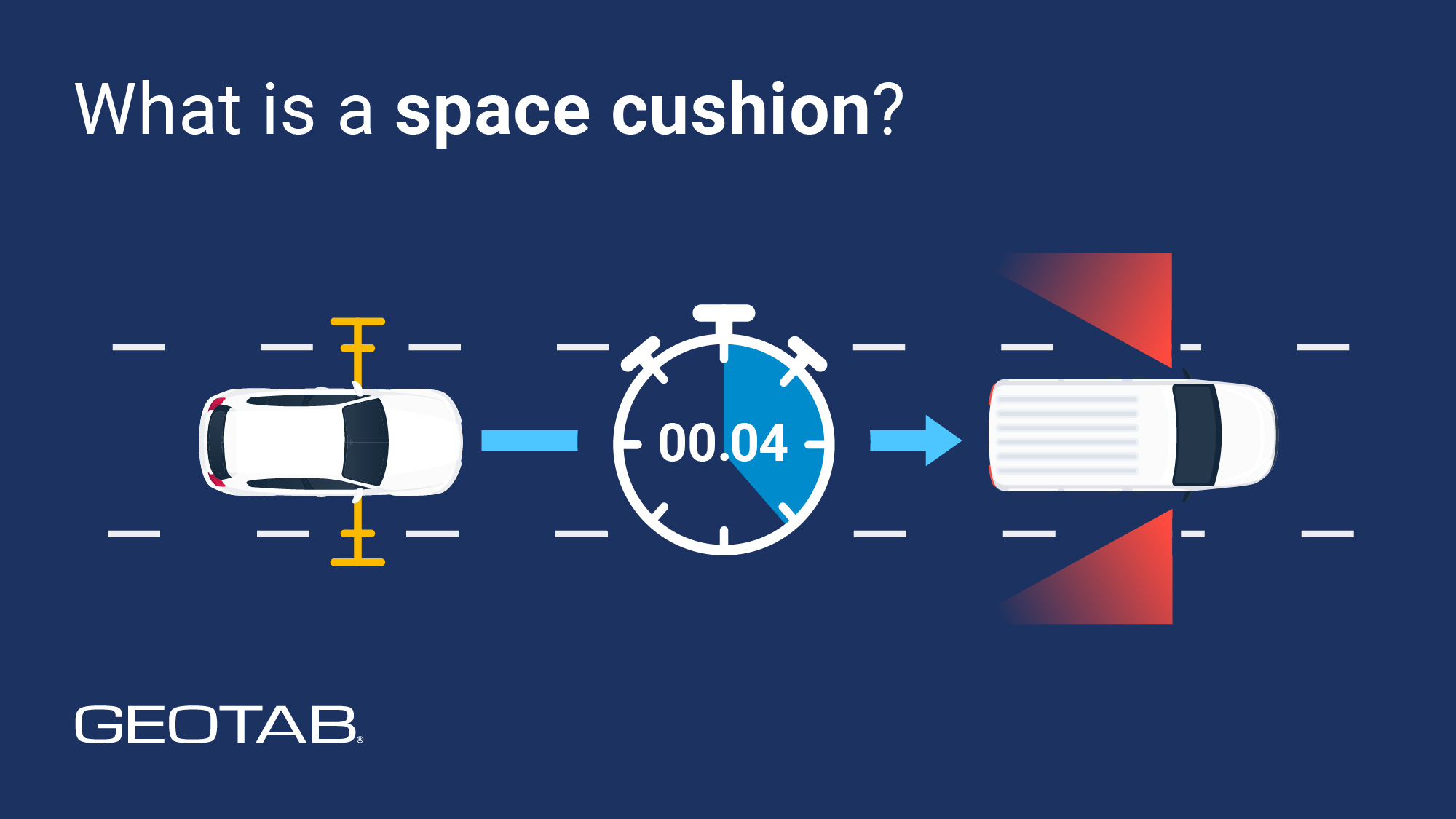

What is a space cushion? A defensive driving guide for commercial drivers

November 13, 2024

3 minute read

What is a safe following distance?

October 8, 2024

5 minute read